Depending on where you are, these important work-horses may go by a range different names like product trolley, product cart or dolly. Whatever the name, the basic structure and function is the same. It has wheels and a load area and is used for moving products from one place to another. However, the functionality, features and complexity can vary significantly from application to application. This article provides an introduction to the wide range of applications where trolleys (or carts) are used, the industries where product trolleys are used and the features that can be added to trolleys making these very versatile and beneficial in the workplace.

Industries and Uses

Product trolleys can be used in a wide range of industries from Automotive to Waste removal, with a range of industries in between like Food, Medical, Production etc. These carts can be as simple as 2 wheels and a load platform that is moved between loading stations to an automated driven vehicle that connects to the product and can have an electronic interface to a workstation on the shop floor.

Application areas where trolleys may be found include:

- Cleanrooms;

- Warehousing;

- Pharmaceutical manufacture;

- Medical Devices;

- ICT server testing;

- Maintenance Areas (Often used for tool storage for repair, setup and change-over operations);

- Sorting offices;

- Product Assembly and material handling;

- Distribution centres;

- Recycling and waste removal.

However, there is no limit to where these carts can be used and as long as material needs to be transferred there is a trolley that can be tailored to the application.

Trolley Features

- Drawers and shelves made from specified materials;

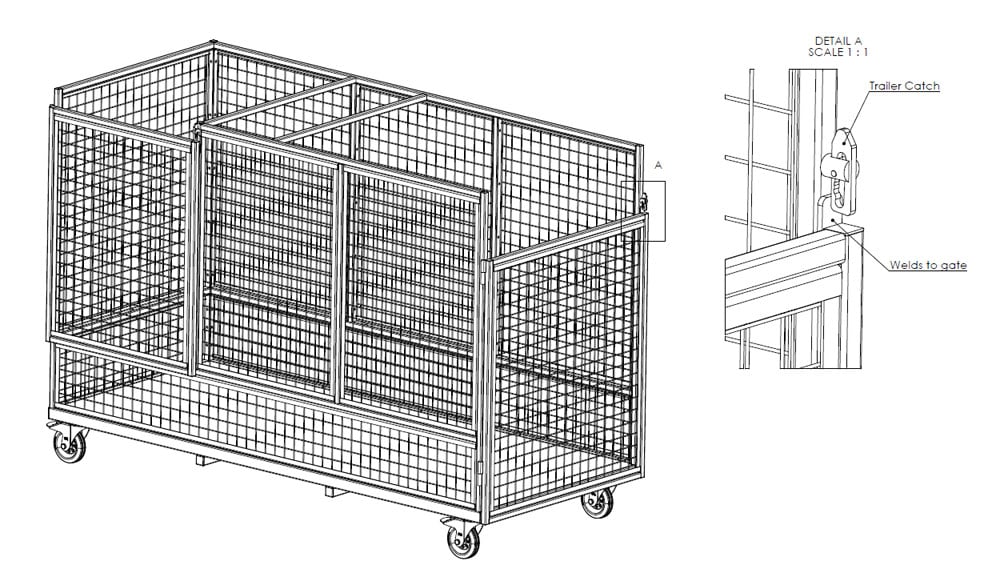

- Swing open doors with trailer latches;

- Wheels / castors

– fixed or easy swivel castors;

– lockable wheels / wheel brakes;

– high stability and high weight castors; - Push handles / folding handles;

- Folding walls that can be latched;

- High load bearing trolleys

– designed specifically defined load capabilities - Compact easy storage trolleys;

- Integrated paddle-lift mechanism;

- Light weight high strength trolley or dolly (weight may be specified with high accuracy);

- Anti-static surfaces for sensitive equipment;

- Containment of dangerous or expensive items – Lockable;

- Tool storage with shadow boards;

- Train movement of trolleys for efficient transport;

- Trolley designs that stack into one another to save space;

- Worktop mounted on a turntable for product orienting;

- Scanner, label, printer holders;

- Customised trolley flights for precise locating of product;

- Customised flight release mechanisms to release the product;

- Wipe-down surfaces free of cavities where bacteria can reside and propagate;

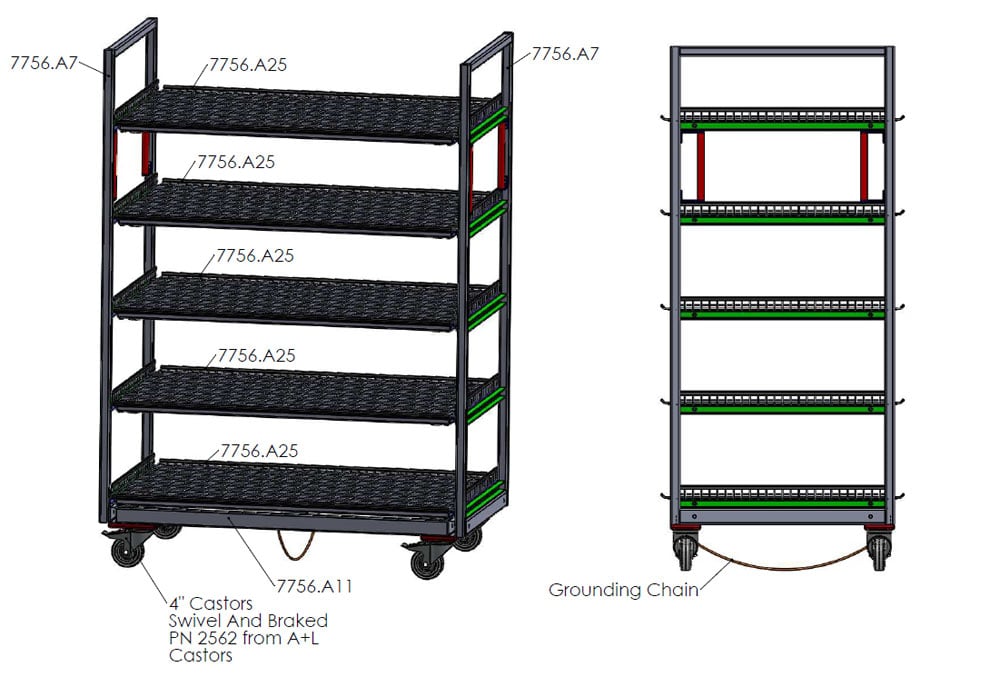

- ESD grounding chains for the purpose of grounding the trolley frame;

- Space saving features;

- Customised safety and security features to meet the product and client needs.

Uses of Product Trolleys

The range of uses for trolleys is too vast to list all the potential uses. Below are only a few uses where NGS Engineering has developed solutions for clients.

- Material movement – trolleys designed to move specified loads;

- Interlocking trolleys for movement as a train of trolleys for optimal movement of product;

- Stabilised server racks designed for the movement of multiple servers while ensuring good earting;

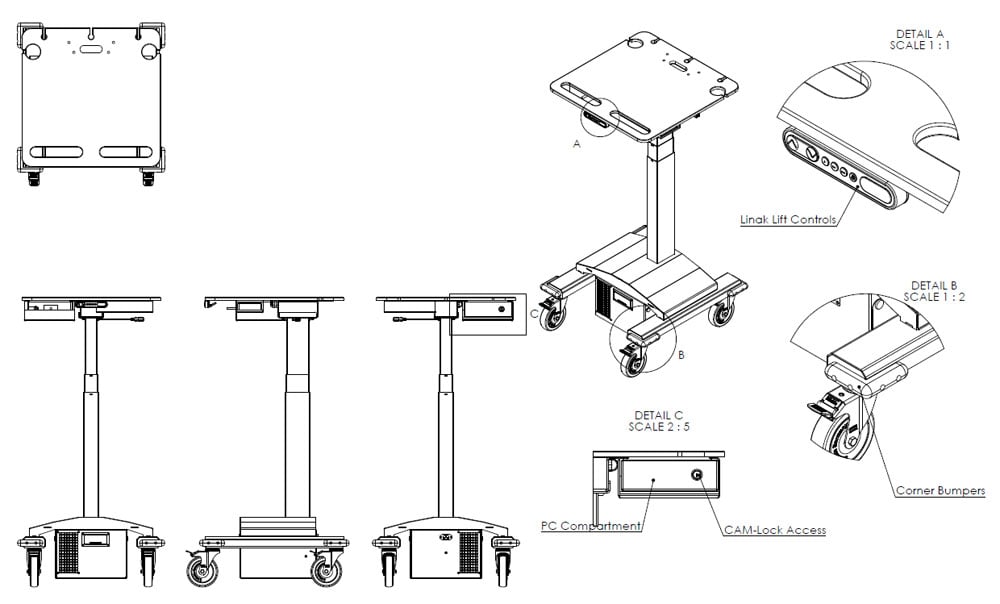

- Trolleys with connected ICT equipment where the orientation of the equipment can be changed;

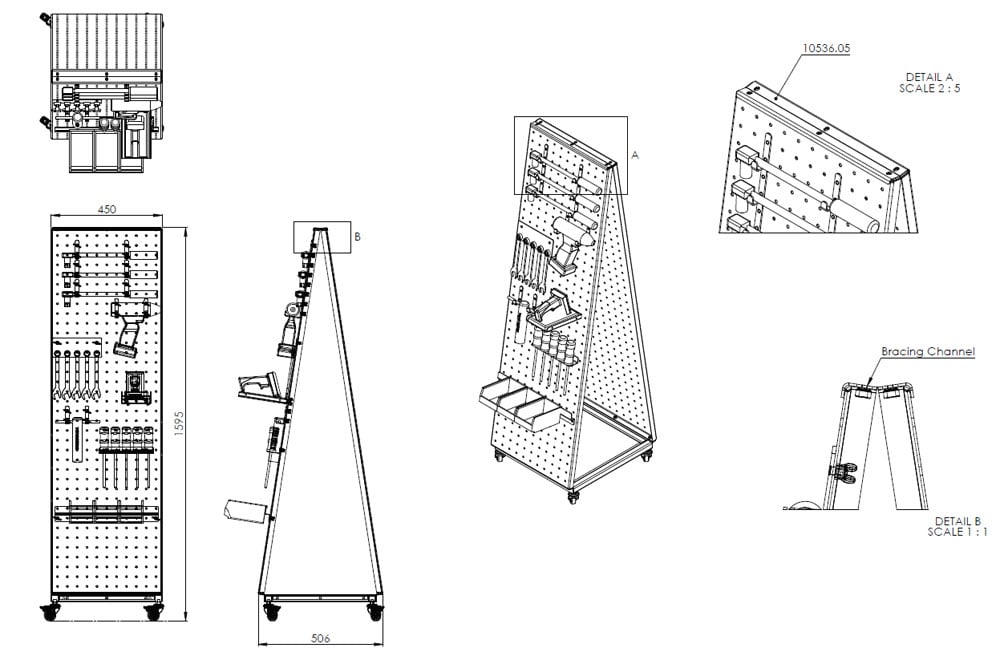

- Tools storage and movement with shadow-boards for use on the shop-floor;

- Waste segregation and recycling trolleys for segregating and moving Cardboard, Plastics, Foam etc.;

- Printer trolley for under desk storage in order to optimise space utilisation;

- Medical device trolleys made from stainless steel with easy wipedown and minimal crevaces where bacteria can accumulate;

- Cleanroom trolleys with high-finish, minimal contamination surfaces;

- Test equipment trolleys with trailing wires for movement between equipment to be tested;

- Labeling trolley for sorting and labelling of post;

- Dolly for safe and secure transport of cylindrical products;

- Mobile workstations – height adjustable carts with an 8 hour power supply for use in a warehouse environment for picking and packing without the need to be plugged into mains power.

Why use bespoke product carts?

Every manufacturing process is unique. The layout of the work area, the operation steps and the movement of material is unique to the process. Pre-existing solutions are not always available or suitable for the process and a wide range of benefits can be realised by designing and building a solution that integrates with the existing process.

The potential benefits include:

- Optimal integration to the existing processes using existing equipment wher applicable;

- Optimal design to reduce operator involvement and minimise manual handling;

- Designed in Lean manufacturing / Poke-Yoke (error prevention);

- Easy and secure movement of product

– cage trolley to increase the amount of product that can be safely move; - Safety and security for operators and product

– product containment to prevent damage;

– security of expensive products;

– containment of dangerous products; - The trolley size can be geared around the pecific product that is carrying, and the trolley can be build to optimise the use of space;

- Operator safety can be improved by eliminating or greatly reducing manual handing of heavy products.

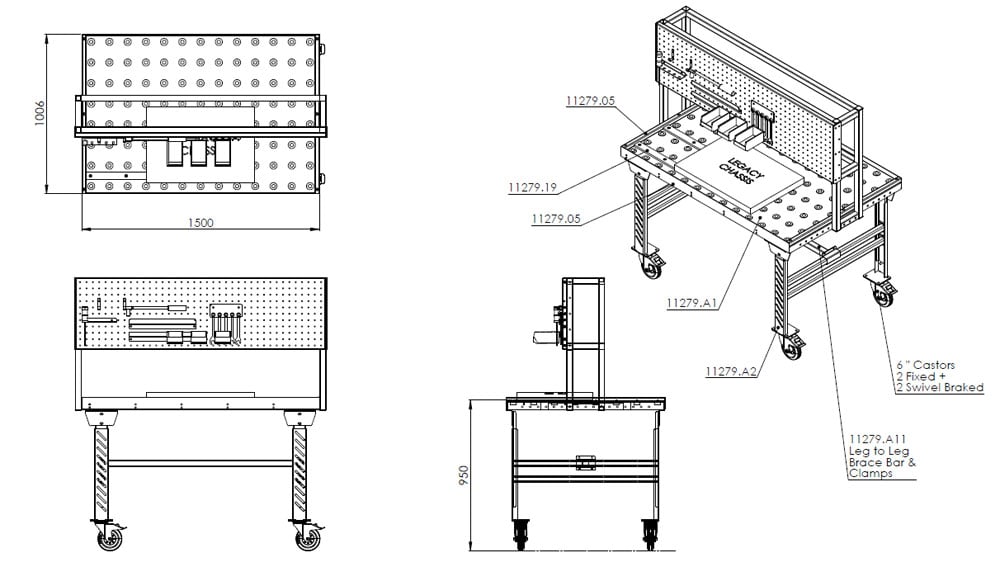

The example below shows Server Trolleys that were designed to work in conjunction with existing infrastructure and to improve the movement of expensive equipment.

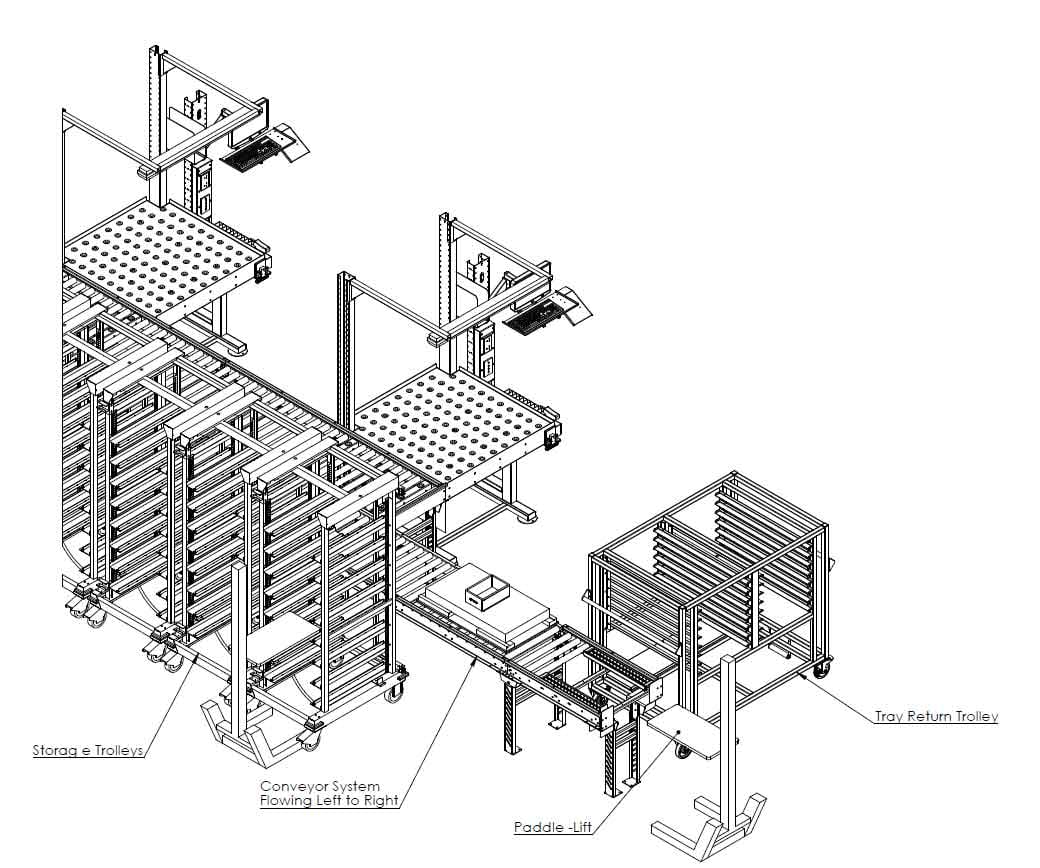

Example – Conveyor system integration

The server trolley and paddle-lift system shown in the image was developed for an ICT client where the requirement was for an existing NGS conveyor system and server racks to be extended in order to provide a total solution eliminating (as far as possible) any manual handling of servers. The requirements also was to automating the process of moving lifting, orienting and placing the servers chassis into existing server trolleys.

The design allows servers which may weigh anything from 30 to 120kg to be moved on a Tray return trolley, lifted using a mobile Paddle Lift and positioned onto a conveyor belt system or ball transfer bearing table for orientation and locating into the server racks.

This implementation successfully used the existing equipment which was fit for purpose while achieving the clients’ requirements to remove any manual handling of the server chassis.