Material Handling Solutions

Material handling is a prerequisite for all manufacturing and storage industries. The safe transport, packaging, labelling and storage of equipment and products is incredibly important to the productivity and profitability within these industries.

The number of companies offering material automated handling systems and robotics solutions within the manufacturing sector has increased as the value of this technology has been realised by companies. Automation and the use of material handling equipment allow for increased productivity, reduction in labour, cost saving, increasing safety and the streamlining of many areas within the manufacturing cycle. This article examines the reasons why the use of automation systems is important, material handling equipment and solutions and the importance of shop floor layouts in heavy industries and manufacturing environments

What is Material Handling?

Material handling can be broadly defined as the movement, protection, safe-storage and control of materials, components and products in production, manufacturing, assembly, packaging and distribution environments

Material handling involves people, process and equipment and covers a wide range of operations which may be manual, semi-automated or fully automated depending on the process and the shop-floor requirements.

The purpose of implementing material handling equipment and solutions is usually to reduce inventory, increase throughput, standardise processes, reduce handling costs, protect products and provide a safer work environment. These may apply to any stage of the manufacturing / production pipeline from procurement through to product delivery.

Manual Handling involves any transporting or supporting of any load by one or more employees, and includes lifting, putting down, pushing, pulling, carrying or moving a load, which because of its characteristics or unfavorable ergonomic conditions, involves risk, particularly of back injury, to employees.

Workplace Safety

Implementation of materials handling processes and procedures can lead to improved safety in the workplace. In the absence of automated material movement solutions, materials, components and products need to be manually lifted and transferred between work areas. This manual handling of materials can lead to injuries and lost time if processes, equipment and training are not adhered to. The HSA-Safety, Health and Welfare at Work, (General Applications) Regulations 2007, Chapter 4 of Part 2 outline the requirements that must be adhered to concerning manual handling.

The key requirements (Regulation 68 of the Safety, Health and Welfare at Work, (General Application) Regulations 2007) are:

- There must be a manual handling risk assessment and an informed decision on what manual tasks can be avoided or reduced

- Organizing tasks to allow for mechanical use to reduce the need for physical manual labour. Allowing for the introduction of machinery to reduce the need for persons on-site through proper layout and implementation of machinery.

- Providing instruction and training to relevant staff.

Although all three points are relevant and need to be adhered to point two is the most important concerning the introduction of material handling solutions. Where and when machinery can take over it should be implemented.

Manual handling activity which needs to be assessed is defined in Regulation 68 of the Safety, Health and Welfare at Work, (General Application) Regulations 2007:

Most back issues are caused by injury and damage to the disc. Unnatural and repetitive movements, especially with the added pressure of increased weight can cause serious damage. This includes bending, twisting and crouching, all which are necessary movements throughout manual handling. More than 24% of all work placement injuries are related to the back.

These guidelines are in place to protect employees and any visitors to shop floors. Manual handling continues to cause injuries in the workplace but with automation and the proper implementation of material handling solutions and equipment, this can be reduced greatly.

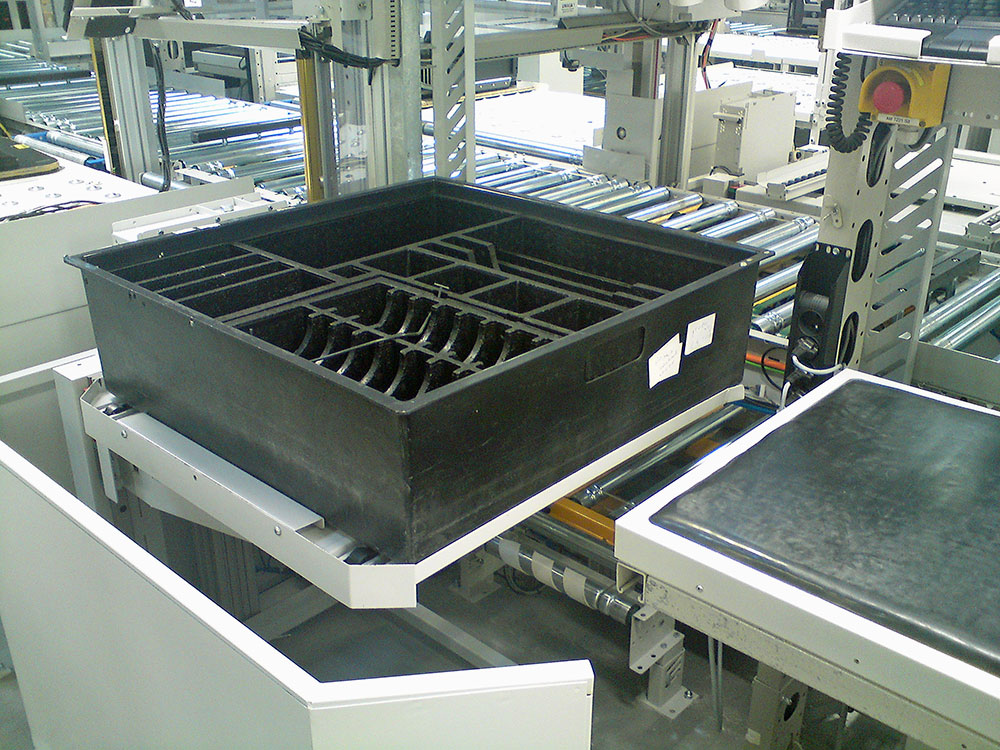

Material Handling Equipment

There are many different types of equipment that can assist in material handling activity and depending on your industry and space available some or all this equipment can be used to assist in operations. Material handling equipment includes all equipment used in the processing and movement of products on a work floor. This includes:

- Conveyor systems, including gravitational, roller pulley and powered systems

- Tote-lifters, hoists, and cranes

- Pick-and-place robotic systems

- Product Assembly stations

- Labelling workstations

- Product Storage

- Protective guarding for equipment and personnel

NGS engineers have the experience and knowledge to ensure the proper design and installation of shop-floor equipment and this can lead to significant benefits to your business. Proper ergonomic designs reduce the need for unnecessary movement and reduced injury; automation reduces the need for physical labour in the workplace and increases throughput; Safe storage protects valuable or dangerous products; and dedicated workstations improve repeatability and customer service.

While each process may be unique, the general principles remain the same and the role of each piece of equipment used fulfills a distinct role within the manufacturing cycle and can be tailored to the shop-floor requirements.

Floor Layout

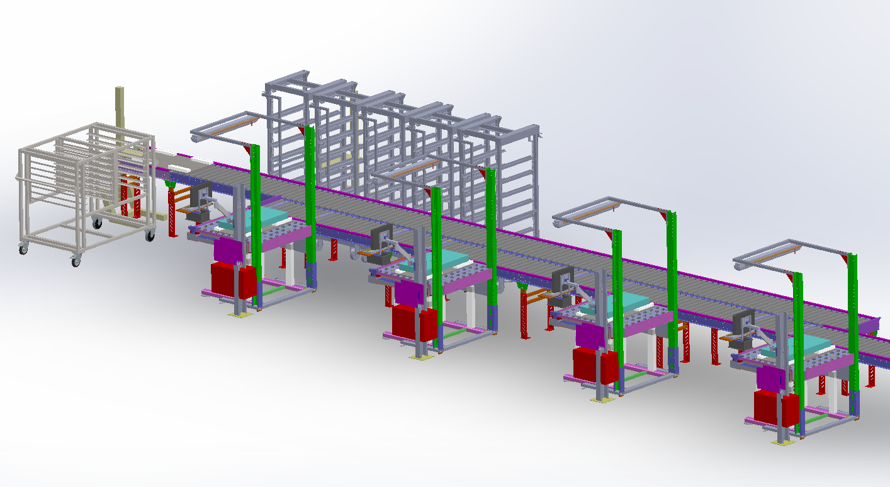

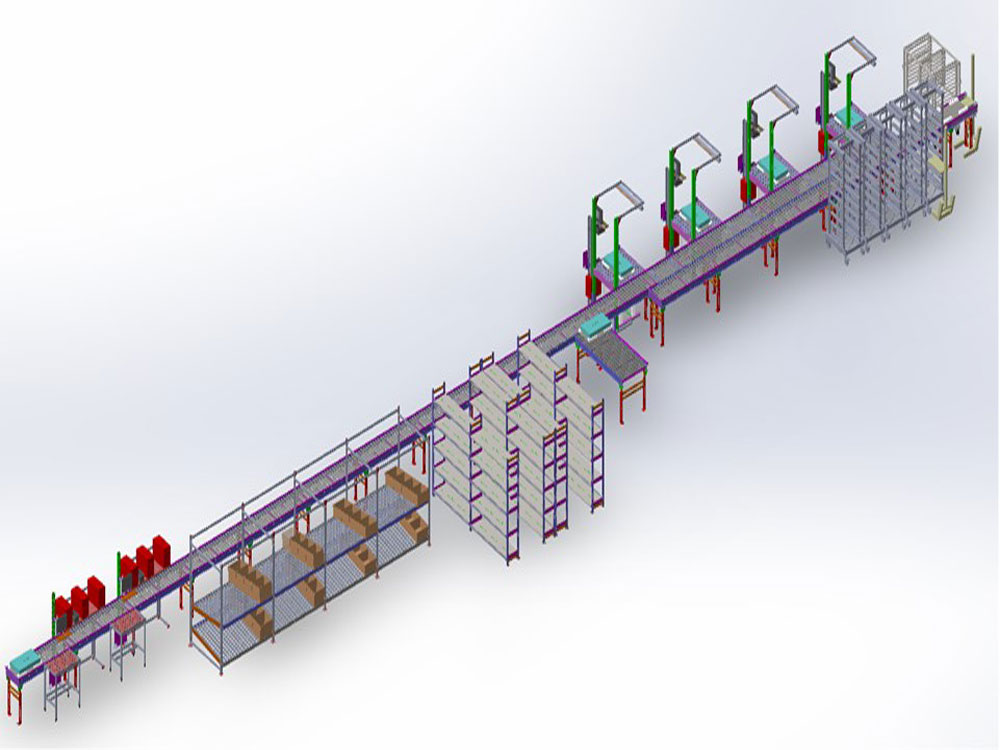

In order for material management equipment to be used to be used in the most effective way, a good floor layout plan is essential. A professional material handling equipment manufacturer, like NGS, works directly with the client to design an layout and then can tailor the equipment to optimally meet the business requirements.

There are several key floor design principles that an industry professional should consider when designing the ideal layout for your material handling solutions.

- Simplification: any unnecessary movement should be eliminated, and the straight-line movement should be used where possible.

- Ergonomics: the workplace should be designed to minimise the chance of repetitive strain injuries and safety should be at the forefront of any design.

- Layout: the layout of shop-floor space should be as efficient with the best possible utilisation of available space and with work areas that are organised and free from clutter.

- Automation: to ensure repeatability and accuracy, automated material handling processes should be implemented where possible.

- Environment: environmental impact in terms of energy usage, wastage and recycling should be considered throughout the design.

NGS Engineering – Material Handling Solutions

Material handling manufacturing professionals such as NGS will work in tandem with you to provide the best results. NGS uses the latest in Computer-Aided Design (CAD), floor plan software and advanced modelling tools to make the best use of space available and that provide the most efficient level of output.

Things NGS looks out for include the use of conveyor systems, workstations, storage area equipment etc. Depending on the industry you are in, NGS has the solution for you.

NGS provides the design and installation of all equipment and supplies needed. In-house engineers build to your specifications and has the in-house expertise to provide tailored workstations and a range of cleanroom solutions. Some of NGS previous installations have included:

- Workstations: These can be designed, manufacture and installed following our client’s needs. Workstations can be self-contained or based on an open plan allowing for labelling, the control of automated machinery on the plant floor and the installation of all necessary software and hardware.

- Conveyor systems: Conveyor systems can be installed into all size workspaces, including both incline and decline accessibility. Conveyor systems are economical, safe and a great asset to any facility with large load-bearing systems in place. They allow for the best in automated material handling.

- Product storage: Depending on the size of your shop floor, robotics and/or conveyor systems can be used to direct products to storage destinations. This is ideal for large assembly stations with multiple streams of manufacturing.

As you can see automated material handling has many benefits and requirements within the manufacturing industry. Get in touch with NGS and they can begin planning the next step in your business’s growth.