Conveyor Systems Design

The conveyor system design requires the expertise of specialized process engineers who have a good understanding of the manufacturing environment and the importance of operator safety, product protection and system efficiency.

The specific conveyor systems design needed for any particular manufacturing process depends on a number of factors including the nature of the materials being transported, the production process requirements, the layout of the workplace and other factors unique to each industry or application.

The most common types of conveyor systems

Belt conveyors: a continuous belt made of rubber, fabric, or metal that moves over a series of rollers and is suitable for transporting a large volume of materials or heavy items.

Roller conveyors: a series of rollers mounted on a frame to transport goods that are particularly useful for moving materials or products in a straight line (or when manual push-assist is required).

Chain Conveyors: a chain that move items along a conveyor path and is best suited to transporting heavy or bulk materials (like pallets or large containers)

Slat Conveyors: Slat conveyors use slats or plates attached to a chain to transport items. They are suitable for moving heavy-duty materials, such as large machines or automotive parts.

Screw Conveyors: a rotating screw mechanism that moves materials along a trough is commonly used for transporting bulk materials or powders (like grains or cement).

Common types of conveyor systems

Overhead Conveyors: a conveyor that is suspended from the ceiling (or elevated structure) and uses chains, cables, or other means to move products (often found in assembly lines or for painting processes).

Pneumatic Conveyors: a conveyor design that utilizes a compressed air system and commonly used for moving powders, granules, or other lightweight materials through pipes or tubes.

Vibrating Conveyors: conveyors that use vibratory motions to transport materials and are best suited for moving fragile or delicate items, such as glass bottles or electronic components.

Magnetic Conveyors: a conveyor design that uses magnets beneath a conveyor belt to move ferrous materials, often found in metalworking or recycling industries.

Bucket Conveyors: buckets attached to a chain or belt that transport materials or products vertically or at an incline and commonly used for handling bulk materials like grains or fertilizers.

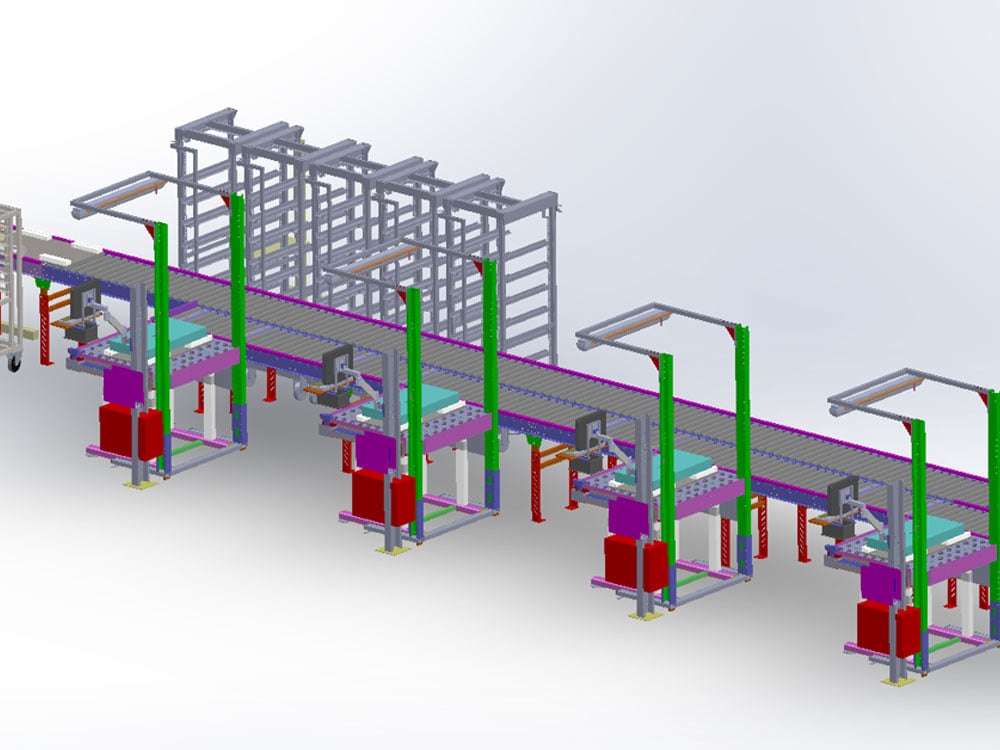

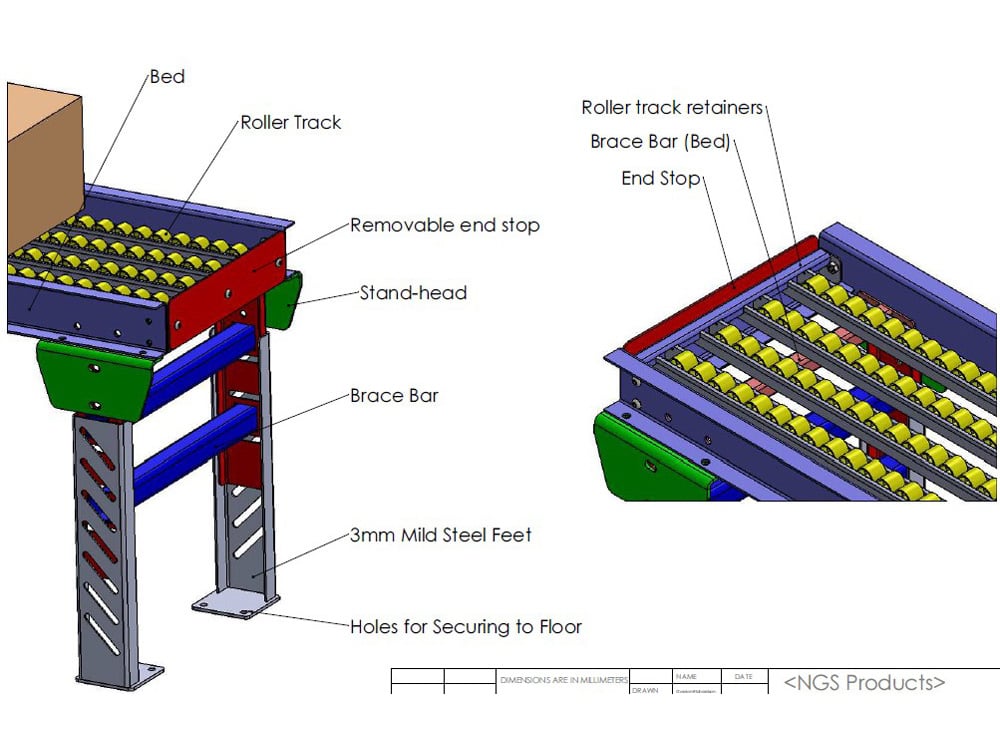

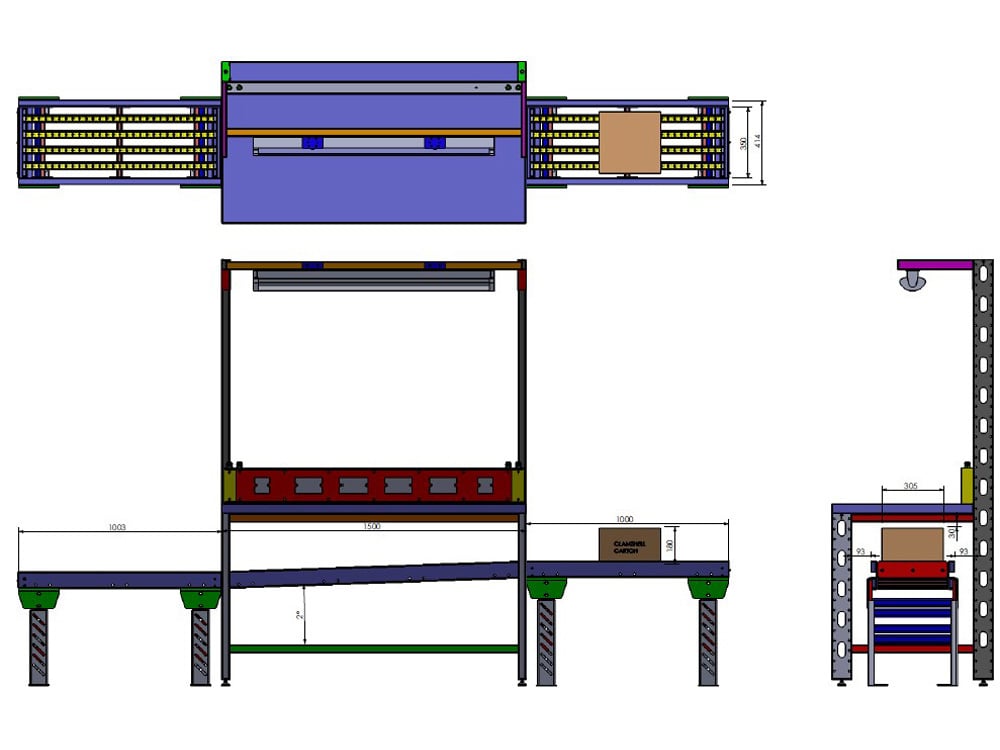

Custom conveyor systems design

Custom conveyor systems design and installation is a niche engineering service that NGS Engineering specializes in – we know there are several essential factors to consider when designing a durable, efficient, and operator-friendly system for manufacturing facilities, including:

- Operator safety considerations/regulations

- Material characteristics & durability

- Throughput requirements

- Layout and space constraints

- Environmental factors

- Ease of maintenance & accessibility

- Power usage

- Integration with other systems

- Budget

- Future line expansion & scalability

- Production uptime

NGS Engineering

Our engineers manage every step of your conveyor system design projects – from the original concept to final installation and commissioning.

If you need an experienced conveyor systems supplier for a current or future project, schedule a needs analysis call with one of our engineering executives to get started.